D&P Construction can help with your cardboard recycling.

Generate rebates from your daily material.

The modern waste industry is recycling more material then ever including corrugated cardboard. D&P Construction has multiple plans to help businesses meet their cardboard recycling needs. Not only will these methods divert material that would otherwise go to costly and wasteful landfills, D&P Construction can help its customers generate rebates that improve their bottom lines.

Depending on the volume created at a given location either a compactor or a baler would be recommended.

D&P Cardboard trailer on route picking up material.

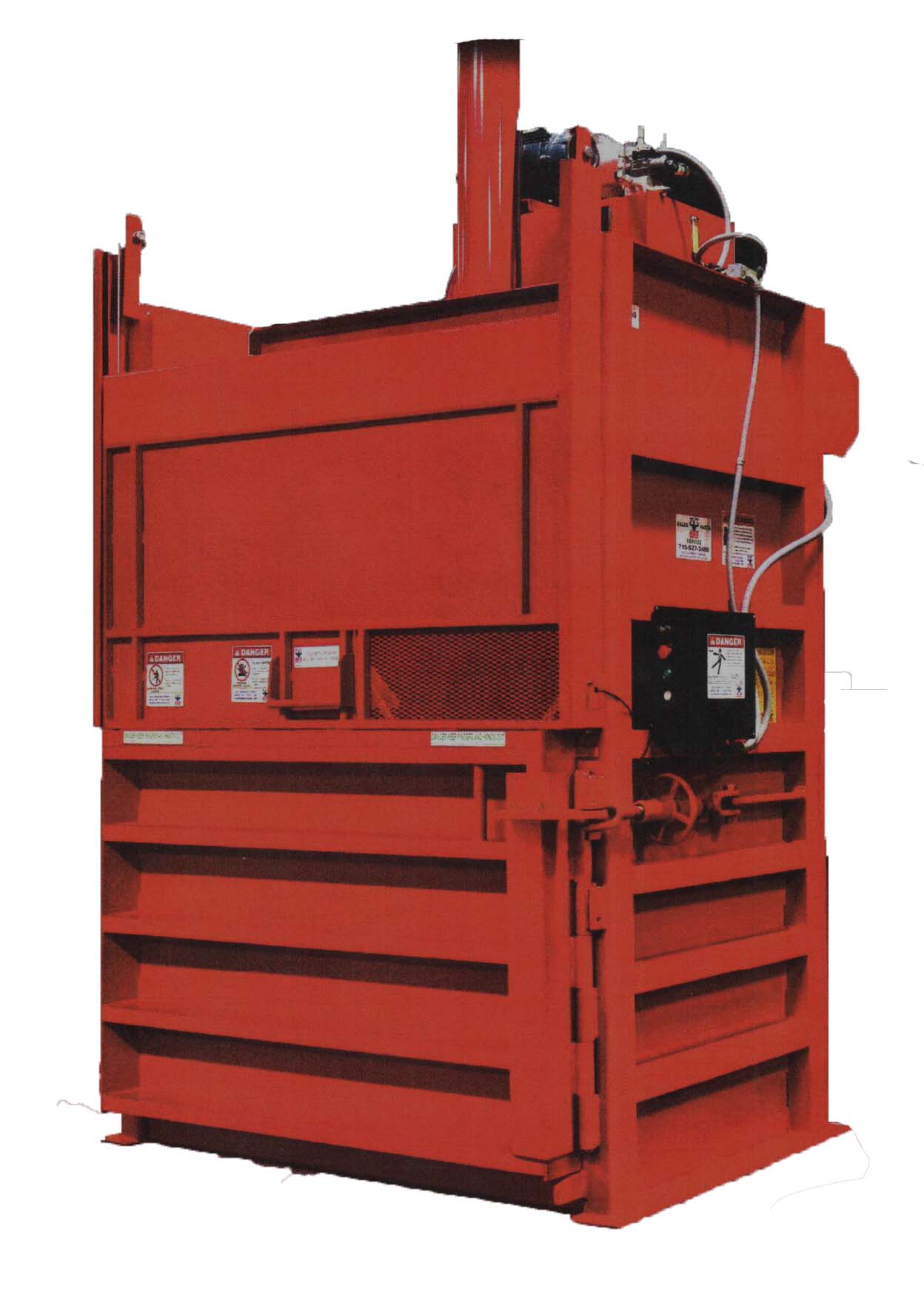

Cardboard Compactor

Cardboard Compactor

Compactors are a powerful and efficient tool to help divert waste to a recycling center. For cardboard a compactor is permanently installed on site and paired with a receiver box. The box can then be switched out at the customers request whenever it becomes full. These switches can be scheduled ahead of time for customers with a steady stream of material. The compactors themselves can be rented from D&P or bought/rented from a third party with D&P’s help. Compactors are a great solution for many customers who do not have the volume to invest in baling as they can ensure each trip contains the most material possible

- Each compactor is customized for its location

- Each compactor has a receiver box attached to it in order to contain the material

- A D&P driver will switch this box out with a replacement when full. Either on call or on schedule.

- Great way to manage material discouraging scavengers.

Cardboard Baler

Vertical Baler for Cardboard

A Baler is a machine that can compress a large amount of material into a dense rectangular cube. It is much more efficient in terms of trucking due to the much higher weight that can be driven into equal volume. More cardboard can be moved per trip reducing transportation costs and increasing rebates generated for customers. A baler requires labor in order to operate. Training is available when a baler is installed. D&P can help its customers choose the right baler solution for any location and more information is available if you contact us at the main yard.

- More efficient then a compactor providing more weight per trip.

- More weight produces larger rebates.

- Bales shouls be kept dry if possible. If storing bales outside D&P recommends a tarp.

- Pickups can be on call or on schedule.

Plastic/Plastic Material

Paper and plastic material can also generate rebates if there is a steady stream of material. Like cardboard the material should be gathered together in bales or a compactor. Mixing material would greatly reduce if not wipe out rebates. Please feel free to contact the Lake St. location for information specific to a certain situation.

- Should be kept with like material free of contaminants.

- More weight produces larger rebates.

- Bales shouls be kept dry if possible. If storing bales outside D&P recommends a tarp.

- Pickups can be on call or on schedule.

- Call the Lake Street office for further information on specific materials.

Material being unloaded at the Lake St. yard.